|

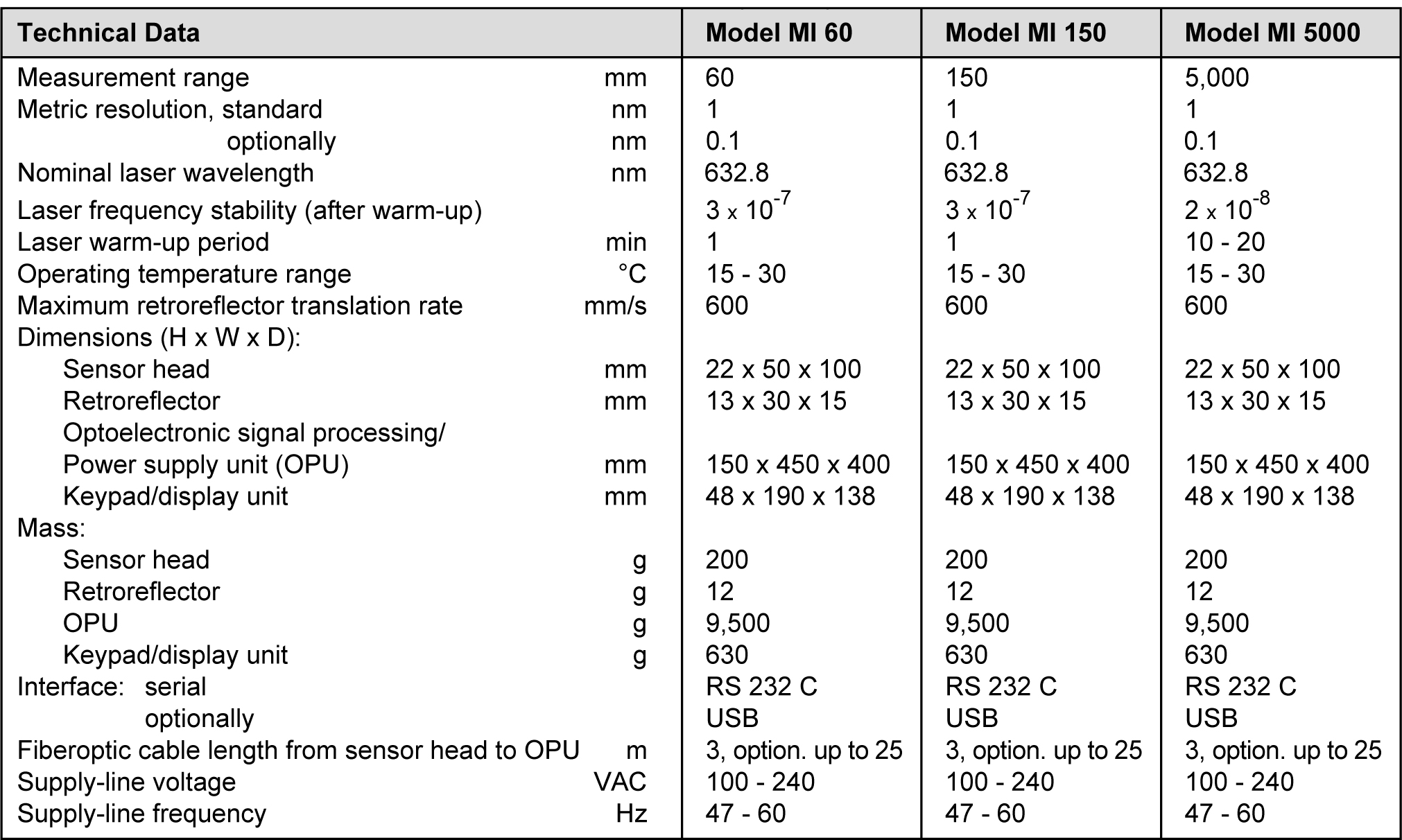

Our MI-Series miniature interferometers equipped with triplefaceted

retroreflectors are precision length measurement

instruments designed for incorporation into customer supplied

systems, and are readily adapted to suit a wide variety of

experimental setups and tasks. The miniaturized sensor head

and triple-faceted retroreflector allow for their employment as

permanently installed metrological systems. The fiberoptic

coupled sensor head provides major benefits in many types of

applications and makes the overall metrological systems more

versatile. The miniature interferometer converts motions of the

triple-faceted retroreflector into optical interference signals that

are transmitted to the opto-electronic signal processing/power

supply unit for processing and output as lengths. A HeNe laser

serves as the light source for the miniature interferometer and

is frequency stabilized on models with large dynamic ranges.

Compensation of environmental influences form the basis for

high metric precisions and are achieved through the correction

of laser wavelengths.

The instruments themselves are free of linearity errors.

Instrument operation and display of measurement results are

controlled either through a separate keypad/display unit or a

PC running the software package supplied

|

• Ultraprecise length measurement instruments

• Versatile instruments for incorporation into

customer supplied systems, readily adaptable

to suit a wide variety of tasks, easy to align

• Allows high retroreflector translation rates

• Insensitive to retroreflector angular

misalignments

• Fiberoptic coupled sensor head

• Causes no thermal interference

• Employs signal-acquisition/transmission hardware

immune to electromagnetic interference

• Employs a HeNe Laser with high frequency

stability as a length standard

• Corrects for variations in laser wavelength

caused by ambient conditions

|

|

• Precision laser interferometric length measurement

instruments for incorporation into single/

multi-axis translation stages, microscope stages,

machine tools, or positioning systems

• Positioning single/ multi-axis machine beds

• Calibrating machine tools or coordinatemeasurement

machines

• Angular measurements

• Handling precision length measurement

|